Waste Water Treatment in Industrial and SMES Sectors

Background

Climate change has become one of the greatest risks that humanity has faced and considered as a high priority of global concerning in the 21st century. As the earth temperature continues to rise, the severity of climate change impacts on global socio-economic development and environmental sustainability continue to intensify and amplify, prompting the need to seek urgent solutions.

Unmanaged industrial waste leaded to impact on human health, environment and also to the increase in GHG emissions in the atmosphere, and these also contribute to cause climate change. Paper, brick and tile factories, rubber/plastic processing and bio-fuel production, if without well management or control, will give a big concern for investment, environmental protection and sustainable development.

To deal with the above issues, this project’s innovation is developed to deal with waste water challenges, to reduce GHG emissions from industrial SMEs’ production processes, to seek for technology solutions for industrial SMEs (mainly food and beverage), to improve regulations/technical guidelines and monitoring capacities, and to explore potential incentive mechanisms.

Overall Objective

Develop an innovative approach to reduce GHG emissions from waste water for SMEs in the food and beverage industry

Specific Objectives

1. Improved knowledge and understanding in MISTI on GHG emissions from industrial waste water and potential technologies for SMEs to reduce these emissions;

2. Low carbon technology and management practices for waste water management are demonstrated;

3. Lessons learned from demonstrations disseminated with government and private sector decision makers; and

4. Strengthened regulatory and financing environment for low carbon IWW management.

Approach

The project will build on information available from UNIDO TEST project and coordinate with UNIDO for information collection on relevant stakeholders and potential targeted companies. The project will consult not only the companies’ owners but also their staff (vulnerable group and women) to share their experiences on keeping and storing waste water.

The overall approach of the project relies on the existing process/system or methodology that have been used by leading institutions, that are MOE/DCC, UNIDO and supported by consultants. MISTI will employ a mix of trainings and on the job capacity building approach for staff and relevant stakeholders on national GHG inventory on IWW sub-sector and demonstration of waste water treatment. This will be done with support from qualified consultants. For the sustainability beyond, the project will provide authorization or support the existing role of Department of Industrial Technique and Safety with under the direct supervision of the General Directorate of Industry.

Outputs and Key Activities

| Result | Key Activities |

|---|---|

|

|

Knowledge Products

• Case studies • Lessons learned and recommendations • Workshops and training manuals • GHG inventory report and its data for industrial waste sector • Technical guidelines/recommendations and any updated regulations on industrial waste water treatment

| Timeframe | Total Budget | Partners | Location |

|---|---|---|---|

|

June 2021 to November 2022 |

USD 132,400 (From CCCA US$100,000) |

UNIDO Phnom Penh Office |

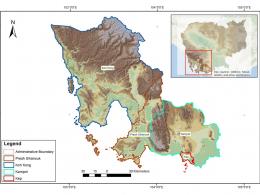

Phnom Penh, Kandal, and Battambang Provinces |